Fanshawe dance club performs a show for sustainability

CREDIT: MAURICIO PRADO

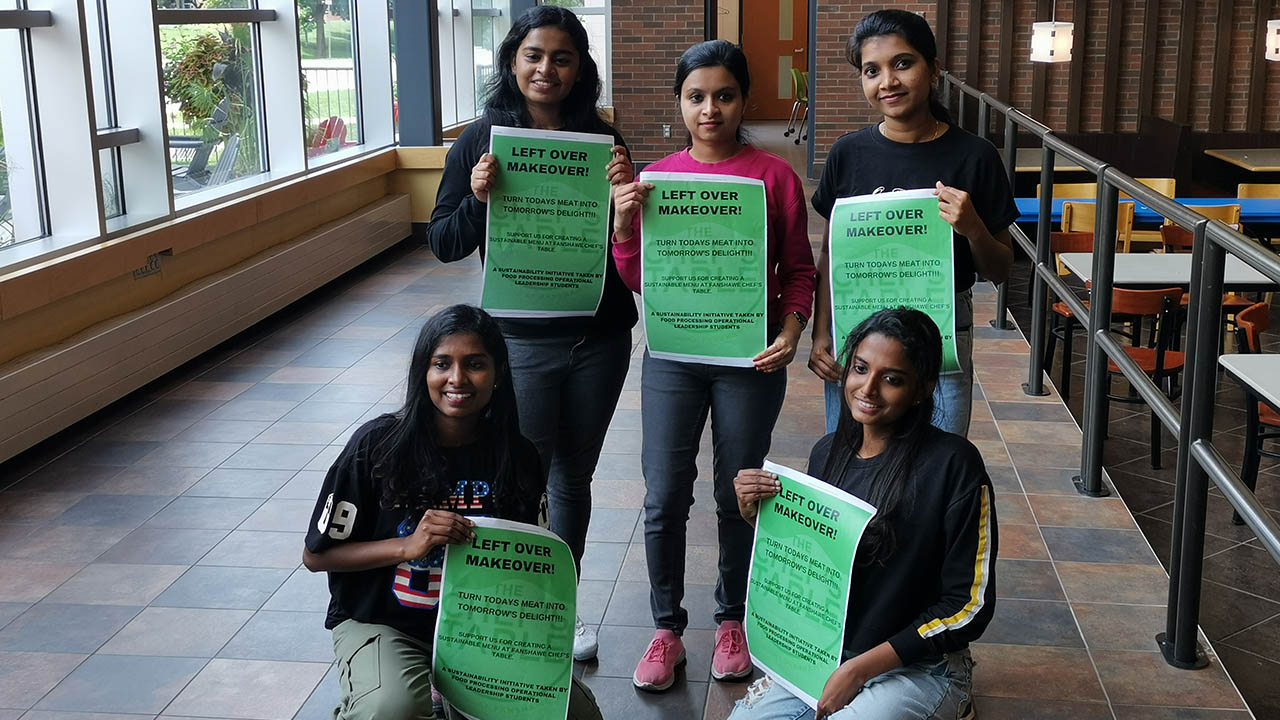

CREDIT: MAURICIO PRADOThe purpose was to convert the meat waste produced at Fanshawe restaurants to a value-added product.

On July 28, Food Processing Operational Leadership students performed a choreographed dance in Oasis to gather signatures to help develop a novel food processing system for sustainability at Fanshawe College. The event, which lasted for one hour, got the attention of around 30 people and included music from different genres. During the event, designated people interacted with the audience to collect their signatures in support of their efforts. The purpose was to convert the meat waste produced at Fanshawe restaurants to a value-added product.

According to Made in CA, meat food waste in households and food services represents 20 per cent of total food waste in the supply chain.

“Out of all the different types of food waste, the waste created when we throw away meat has the biggest environmental impact. That is why we are trying to spread the word in Fanshawe College,” said Fanshawe Food Processing Operational Leadership student Amritha Daniel.

Daniel added that the waste of meat is responsible for one-third of the emissions caused by food waste. She said that even though it only makes up 20 per cent of all food waste, wasted meat takes up 3/4 of the land used by food waste.

“We are trying to show the process of drying meat,” Daniel said. “Meat lasts six to 10 days depending on whether or not it is cooked, and dried meat lasts 15 to 20 days.”

Daniel said the meat needs to be adequately cured to do the drying process safely. She added that the purpose and challenge of a good curation process is to minimize water activities.

“A salt-based treatment eliminates water and makes the environment uninhabitable for germs. The next step is to put it in the fridge for a few days.” Daniel said. “Hang it in a controlled area after a few days when the salt has already had a chance to penetrate and remove some moisture. Maintaining a constant airflow and temperature is key to minimizing water activities.”

She said a controlled environment can be achieved using a dehydrator, a low-temperature oven, or a microwave. Daniel added that this method is the easiest method of meat preservation.

“The beef is shelf stable once all the previous steps have been accomplished. It may be kept on the counter. However, putting the beef in the refrigerator or freezer will increase its life and prevent it from drying out too much to maintain it as flavorful as possible,” Daniel said.

Daniel stated that everybody should do this process with the meat to minimize its waste, as processing meat for consumption already requires far more procedures and resources than growing and processing fruits and vegetables.

“Through this, we aim to achieve some Sustainable Development Goals such as reducing food waste, zero hunger and responsible consumption and production,” Daniel said.